Keep in touch!

Stay up to date with us by following our [News & Updates / LinkedIn Feed] as we continue to publish more articles, along with environmental reports and data sheets about our operations.

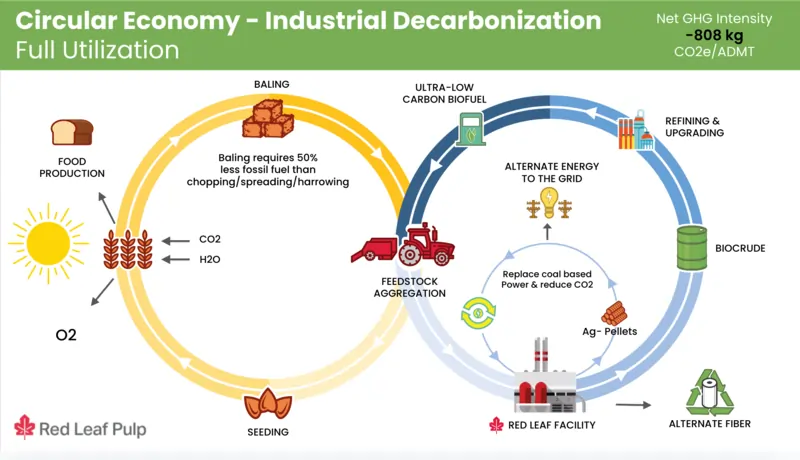

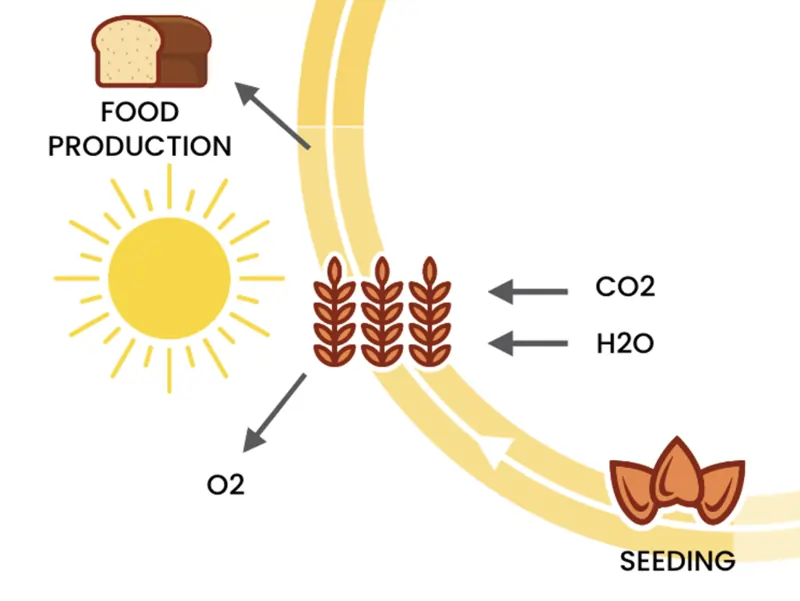

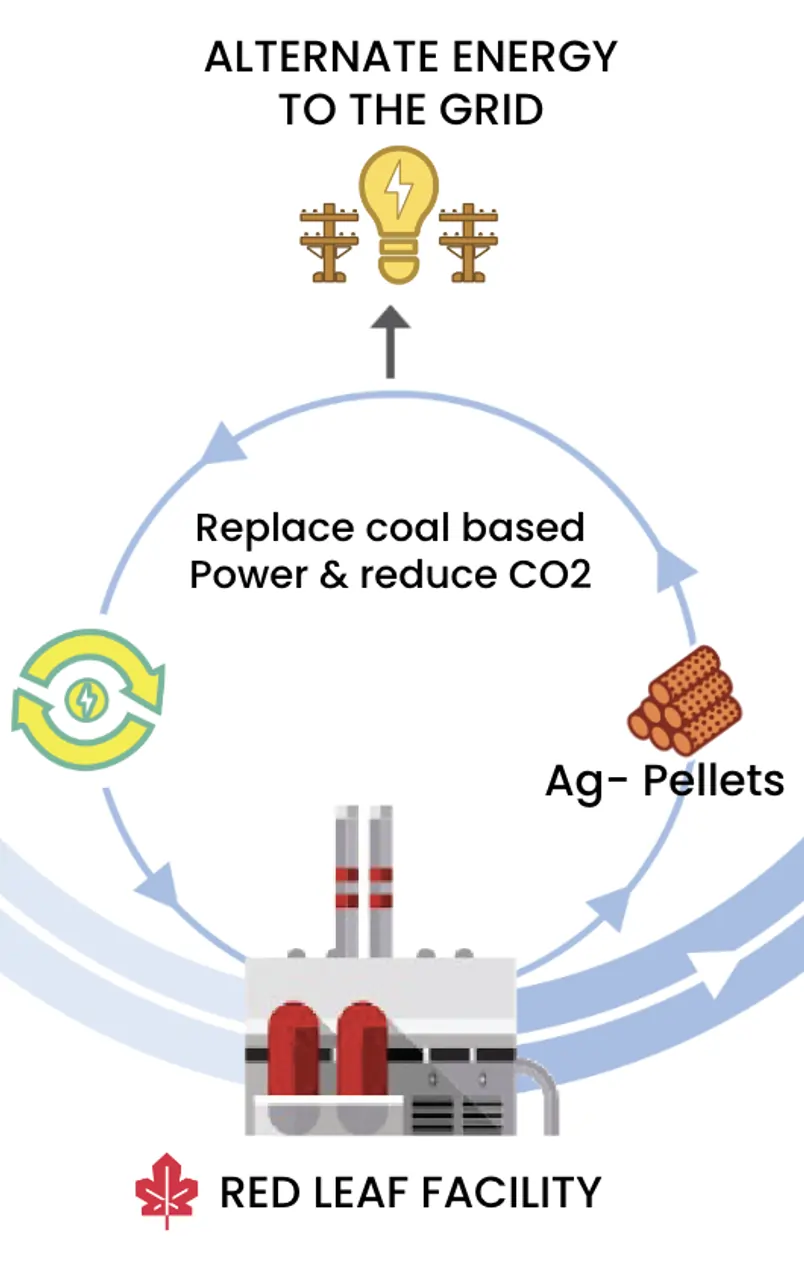

Review a magnified view of our Circular Economy diagram here.